Spencer Farr

HDD Field Specialist

Bo Schwenckert

Underground Sales Rep

Carlos Charles

Borestore/Underground Rep

Daniel Luna

Environmental Sales Rep

Jaden Mason

Borestore Specialist

Vermeer Quality HDD Tooling is engineered to maximize efficiency and productivity. With unmatched durability, these tools are an investment in long-lasting, dependable equipment.

The Vermeer Ultra X3 features interchangeable pilot and pullback tooling, eliminating the need for torqued or threaded components. Its innovative design allows reaming directly off the transmitter housing, reducing costs by eliminating the need for starter rods and adapters in certain applications. With a robust spline connection, the Ultra X3 handles reaming diameters up to 10 inches (25 cm) off the transmitter housing in most conditions, delivering reliable performance and efficiency.

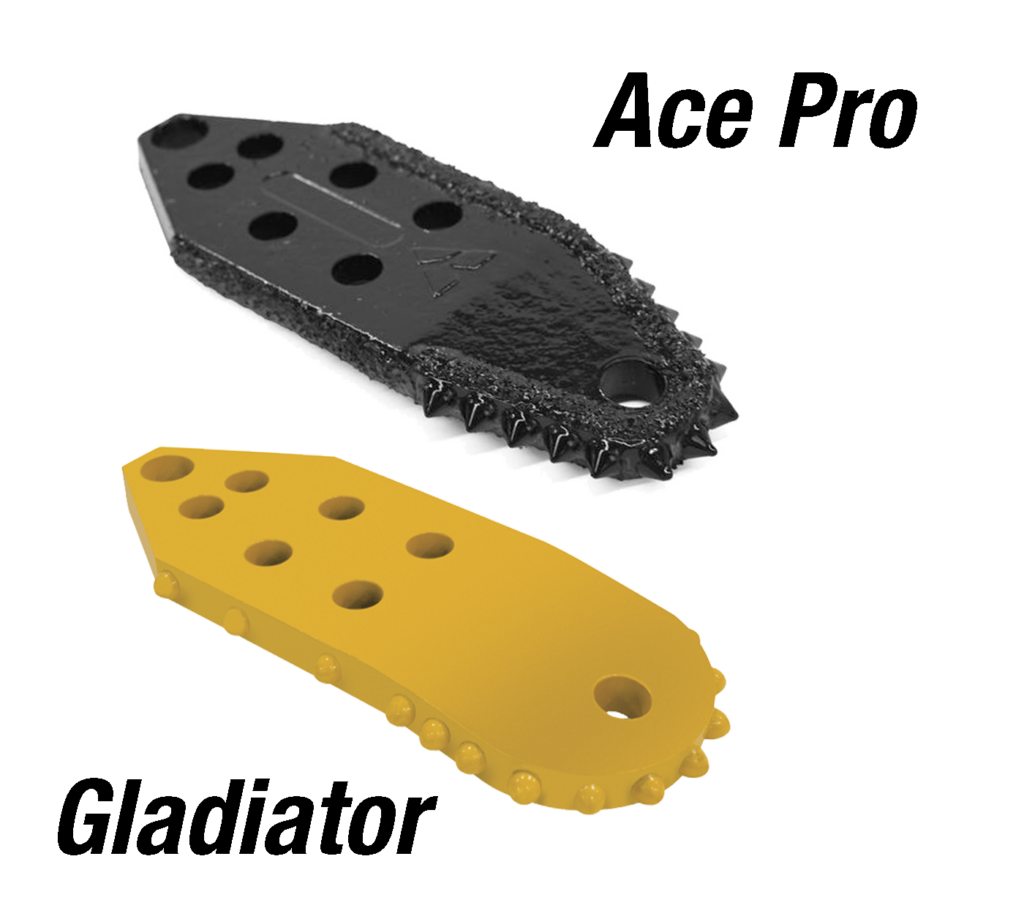

Vermeer offers a comprehensive selection of Ace and Gladiator bits, each designed to handle diverse soil and ground conditions with ease. Ace bits feature a plug-style tooth design, positioning teeth closer together for maximum carbide coverage and extended wear life. Similarly, Gladiator bits are engineered for durability, featuring oversized carbide buttons to reduce premature wear and enhance longevity. Together, these bits provide reliable, long-lasting solutions for your toughest drilling challenges.

Vermeer offers a comprehensive lineup of HDD reamers designed to handle a wide range of challenging ground conditions. From cobble and soft rock to hard pan and chunk rock, Vermeer reamers deliver superior performance and durability.

The Fluted Reamer features a robust through-shaft design, heat-treated cast-alloy steel, and carbide mesh grit for extended life. Its rotary or shark teeth create aggressive cutting action, ideal for rugged conditions.

The Mix Master HD Reamer is built on an API Reg Box x Pin with thick, gusseted plates for improved durability. Its open sections enhance fluid flow, while rotary teeth in a spiral cutting pattern create smooth and efficient reaming. Fluid ports distribute evenly to maintain bore integrity and clean the cutting teeth.

For larger jobs, the Supreamer Reamer offers an open-body design with large paddles for superior mixing action. Its oversized shark teeth provide aggressive cutting and easy pushback, making it perfect for demanding projects.

The T-REX Reamer tackles the toughest conditions with a steep, rear-tapered design and high-alloy steel construction. Its carbide mesh grit hardfacing and oversized shark teeth ensure smooth cutting and long wear life. Optional built-in swivel or through-shaft designs add versatility for challenging terrains.

Vermeer reamers combine durability, precision, and versatility to meet the needs of any HDD project.

To help you maintain pinpoint precision on the job, we carry all of the latest locating equipment. including the popular DigiTrak Falcon F5 Guidance System, DigiTrak® Aurora® Display, as well as McLaughlin utilitylocators and probes.

Right Turn Supply offers a comprehensive range of HDD drilling additives designed to enhance drilling performance. Their products include clay and shale inhibitors, surfactants, thinners, defoamers, foaming agents, and viscosifiers, all formulated to optimize drilling efficiency and manage various ground conditions.

Mincon’s HDD hammers are engineered for high-frequency performance, delivering 2,100–2,300 blows per minute. This design reduces shock load on steering electronics and the drill string, enhancing durability and efficiency. Compatible with standard directional drill rigs and DCI locating systems, Mincon hammers ensure seamless integration into your existing HDD operations.

Vermeer Mountain West offers a specialized bit repair service to help extend the life of your HDD drill bits, saving you money and ensuring optimal performance. These highly specialized bits are designed for specific ground conditions and soil types, and regular wear is inevitable on demanding drill jobs. Repairing worn bits is a cost-effective alternative to buying new ones, providing significant savings while maintaining productivity.

Timely repair is essential—bits must be serviced before reaching an advanced stage of wear to remain repairable. Unfortunately, many customers wait too long, missing the opportunity to restore their equipment. By emphasizing early intervention and routine maintenance, we aim to help you maximize the value of your tools while supporting the efficiency of your operations.